STM Test Center – Experimental Work

Located in Villach, Austria, STM Test Centre operates a state-of-the-art laboratory facility dedicated to advancing grinding technology in mineral processing. This cutting-edge lab functions as a hub for innovation and research, equipped with a range of specialized equipment and staffed by experts in the field.

Central to the test facility are the various lab and pilot mills, which range in size from 5 to 300 liters. These mills provide a versatile platform for comprehensive testing and optimization of grinding processes. Whether exploring new production mill designs, fine-tuning grinding rotor configurations, or evaluating the performance of wear parts, the lab’s array of mills enables precise experimentation and analysis.

Furthermore, the team’s expertise in mineral processing is unmatched. With years of experience and profound domain knowledge, they possess a detailed understanding of the complexities involved in achieving optimal grinding performance. From selecting the perfect grinding media composition to fine-tuning slurry density and circuit configurations, their insights foster innovation and efficiency in mineral processing operations.

In addition to mill testing and optimization, the lab also performs media wear tests to assess the durability and performance of grinding media under various operating conditions. By carefully examining wear patterns and material characteristics, they provide valuable insights for selecting the most suitable grinding media for specific applications, ultimately optimizing operational efficiency and reducing maintenance costs.

In summary, the laboratory facility in Villach stands as a testament to Swiss Tower Mills Minerals’ commitment to advancing of grinding technology. Equipped with a range of lab and pilot mills, along with expertise in mineral processing and media wear testing capabilities, the facility is a crucial center for research, innovation, and industry collaboration.

Simulations

STM uses state of the art computational methods to optimise the mill structure and grinding process, such as:

- Static and dynamic finite element simulations to evaluate the structural integrity of the complete mill

- Discrete element simulations to investigate the grinding media bed dynamics and optimise the internal components to enhance the grinding performance and reduce the wear

- Computational fluid dynamics are used to catch complex slurry flow patterns and fluidisation of the grinding bead mass

Product Development

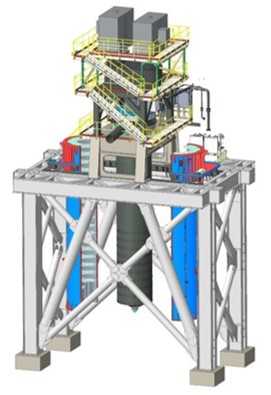

STM is consistently planning for the next generation of vertical stirred mills whether for coarser grinding application or larger mill sizes to handle higher throughputs:

- Fully in-house developed grinding media system. A fundamental part for larger mill size applications.

- Development 75,000 L / 11 MW mill.

Biggest vertical stirred mill EVER, dual motor currently in the design phase. - Coarse grinding applications.

STM is targeting the application of stirred milling to coarse grinding by developing ad hoc solutions for the internals and externals of the grinding chamber.